Integrated annual report

(financial & sustainability report)

2024

Foreword

“Through research and innovation, we’re looking for the most sustainable solutions to maximise our positive impact.”

In December, I became the new chairman of Aquafin, a decision I did not have to think long about. Over the past few years, as chairman of De Vlaamse Waterweg, I visited a lot of projects connected with the Sigma Plan. Projects of crucial importance to protect us against the flooding of the Scheldt and its tributaries.

The extreme showers – veritable water bombs even – that we are now also seeing in Flanders are proof that the threat is real. While at the same time, the availability of potable water in the same Flanders may even become a problem in the long term. So if I can be of any significance to a company that makes it its mission to create a living environment in harmony with water, then I consider it an obvious choice.

Climate change also has a major impact on the cost of water treatment. 2024, the wettest year on record in Belgium, brought a record volume of incoming sewage water to treatment plants: no less than 1 billion m³ or a quarter more than in an average year. Despite this huge challenge, we ended 2024 with a commendable 97.26% of waste water treatment plants meeting all applicable standards.

A large flow due to dilution caused by an extremely high volume of rainwater not only means more pump capacity and therefore energy. It also makes itself felt in higher sludge processing costs and more chemicals in order to comply with treatment standards which are stricter in Flanders than the ones imposed in Europe. This new context not only makes you think about the real added value of these stricter standards but also about the formula of the current remuneration model.

What matters is that our streams and rivers become healthy again. Good quality treated waste water is essential for that but there is still work to be done to further expand and optimise the sewer system. Through the projects that we delivered in 2024 for the Flemish Region, we reduced nitrogen emissions into the watercourse by 615 tons per annum and phosphorus emissions by 138 tons per annum. In the meantime, we have also been helping towns, cities and municipalities realise their reduction objectives and carrying out research and innovation in order to find the most sustainable solutions for maximising our positive impact and reducing our ecological footprint.

In that context, the permits that Aquafin acquired last year for the construction of two new sludge dryers that run on residual heat and a sludge mono-processor with recovery of energy and raw materials represent a real milestone. You can read all about it in this annual report which, for the first time, also includes a comprehensive sustainability report.

Koen Anciaux

Chairman of the Board of Directors

2024

at a glance

Expansion of collaboration with drinking water companies

In 2024, Aquafin and Pidpa took over sewer management in 46 additional cities and municipalities. This collaboration, which started in 2023 with 5 municipalities, was further expanded. Pidpa is now the third drinking water company, after water-link and De Watergroep (Riopact), with which Aquafin has a structural partnership.

After taking over sewer management in Aalst together with Farys, Dendermonde also entrusted its sewer management to the Aquafin-Farys tandem in 2024.

We aim for more structural collaborations with Flemish sewer managers to reduce fragmentation and increase efficiency.

Establishment of Aqcelerator as a venturing company

On 8 February, Aqcelerator was launched as a new entity under the Aquafin banner. This venturing company serves as a lever to innovate with third parties and thus increase societal impact. Aqcelerator has two objectives:

- Unlocking common goods for reuse, such as treated wastewater, heat and rainwater.

- Stimulating market innovations.

AquaMarkt promotes circularity

AquaMarkt is a digital platform that unlocks the potential of treated wastewater, heat from sewers or treated wastewater (riothermie) and rainwater. It provides a clear and accessible system for interested parties to make use of these ‘common goods’.

With clear procedures and just a few clicks, parties can express their interest. A public announcement also gives others the opportunity to bid or collaborate on a project proposal.

Aquafin objectively evaluates the proposals and selects the project with the greatest positive impact.

Building the future of sustainable sludge treatment

A new chapter in sludge processing is on the horizon. From 2027, our treatment process will take a major step forward—with a significantly smaller environmental footprint. This includes two CO₂-neutral belt dryers and a state-of-the-art mono-processor, currently under construction. The belt dryers will use residual heat to transform sludge into compact, high-energy pellets.

These pellets will be used to produce high-pressure steam in the mono-processor located at the ArcelorMittal site. This steam will serve as a fossil-free energy source in their industrial processes, replacing fossil fuels.

With this investment, we’re advancing towards a circular economy and enabling cleaner, more efficient sludge treatment—a win for both industry and the environment.

Partner Academy with engineering companies

With the Connecting Collaboration charter, Aquafin, together with several engineering companies, is focusing on a collaboration model based on connection, trust and inspiration. Always with the necessary attention to the well-being and development of project team members.

In 2024, we launched a Partner Academy to share the knowledge needed for our projects. We offer a range of courses, from technical training to workshops on relational intelligence. This promotes knowledge sharing, creates a common language and stimulates shared leadership.

Award-winning sustainable road design

In Turnhout, we proved that sustainable water management is possible even in dense urban areas. Our innovative sewerage project in Nonnenstraat tackled the challenge of limited space with a smart, underground solution.

Together with our engineering partners, we developed a pioneering road structure using hollow concrete blocks placed just beneath the surface. Rainwater from the street, pavements, and front roof sections is collected through permeable gully grates and directed into a specially designed porous foundation layer. There, the water is buffered and gradually infiltrates into the soil. This approach transforms the entire road surface into an active infiltration zone – reducing the risk of flooding and helping to replenish groundwater levels.

Our efforts didn’t go unnoticed. In 2024, the project proudly received the FEBE Elements Award in the Outstanding Precast category.

Expansion of collaboration with drinking water companies

In 2024, Aquafin and Pidpa took over sewer management in 46 additional cities and municipalities. This collaboration, which started in 2023 with 5 municipalities, was further expanded. Pidpa is now the third drinking water company, after water-link and De Watergroep (Riopact), with which Aquafin has a structural partnership.

After taking over sewer management in Aalst together with Farys, Dendermonde also entrusted its sewer management to the Aquafin-Farys tandem in 2024.

We aim for more structural collaborations with Flemish sewer managers to reduce fragmentation and increase efficiency.

Building the future of sustainable sludge treatment

A new chapter in sludge processing is on the horizon. From 2027, our treatment process will take a major step forward—with a significantly smaller environmental footprint. This includes two CO₂-neutral belt dryers and a state-of-the-art mono-processor, currently under construction. The belt dryers will use residual heat to transform sludge into compact, high-energy pellets.

These pellets will be used to produce high-pressure steam in the mono-processor located at the ArcelorMittal site. This steam will serve as a fossil-free energy source in their industrial processes, replacing fossil fuels.

With this investment, we’re advancing towards a circular economy and enabling cleaner, more efficient sludge treatment—a win for both industry and the environment.

Establishment of Aqcelerator as a venturing company

On 8 February, Aqcelerator was launched as a new entity under the Aquafin banner. This venturing company serves as a lever to innovate with third parties and thus increase societal impact. Aqcelerator has two objectives:

- Unlocking common goods for reuse, such as treated wastewater, heat and rainwater.

- Stimulating market innovations.

Partner Academy with engineering companies

With the Connecting Collaboration charter, Aquafin, together with several engineering companies, is focusing on a collaboration model based on connection, trust and inspiration. Always with the necessary attention to the well-being and development of project team members.

In 2024, we launched a Partner Academy to share the knowledge needed for our projects. We offer a range of courses, from technical training to workshops on relational intelligence. This promotes knowledge sharing, creates a common language and stimulates shared leadership.

AquaMarkt promotes circularity

AquaMarkt is a digital platform that unlocks the potential of treated wastewater, heat from sewers or treated wastewater (riothermie) and rainwater. It provides a clear and accessible system for interested parties to make use of these ‘common goods’.

With clear procedures and just a few clicks, parties can express their interest. A public announcement also gives others the opportunity to bid or collaborate on a project proposal.

Aquafin objectively evaluates the proposals and selects the project with the greatest positive impact.

Award-winning sustainable road design

In Turnhout, we proved that sustainable water management is possible even in dense urban areas. Our innovative sewerage project in Nonnenstraat tackled the challenge of limited space with a smart, underground solution.

Together with our engineering partners, we developed a pioneering road structure using hollow concrete blocks placed just beneath the surface. Rainwater from the street, pavements, and front roof sections is collected through permeable gully grates and directed into a specially designed porous foundation layer. There, the water is buffered and gradually infiltrates into the soil. This approach transforms the entire road surface into an active infiltration zone – reducing the risk of flooding and helping to replenish groundwater levels.

Our efforts didn’t go unnoticed. In 2024, the project proudly received the FEBE Elements Award in the Outstanding Precast category.

About Aquafin

330

Wastewater treatment plants (WWTPs)

2090

pumping stations and storage settlement tanks

7429

km of pipes

1300

Aquafin employees

673

mio € turnover

1232

projects in progress

for the Flemish Region

97.3

% of WWTPs compliant to

all applicable standards

153

cities are a customer

87.6

% of the residents of Flanders

are connected to wastewater treatment.

Our vision

“Clean watercourses for future generations and a living environment in harmony with water”

In Flanders we will take care of the treatment of domestic waste water and find space for water. To do that, we will build and manage a transport network for wastewater, wastewater treatment plants, infiltration and buffer elements for rainwater.

With smart infrastructure, we can strengthen climate resilience in Flanders and help create a pleasant and healthy living environment for people and nature. We consider the careful use of water and raw materials essential to that vision of the future. Therefore we are not only helping keep the water cycle intact, we are also making our own operations sustainable.

Strategy, developments & challenges

“Simplification and standardisation to counteract increasing complexity”

In 2024 – an electoral year – Aquafin was able to convince the new Flemish Government to further increase the pace of investment in wastewater treatment infrastructure and to improve the alignment of municipal and supra-municipal investments in the process. A crucial strategy for healthy watercourses, according to CEO Jan Goossens. At the same time, he sees that there are a few other hurdles that will need to be overcome.

What developments stand out when we look back at the past year?

“We have seen it for a number of years and it was confirmed once again last year: the context we work in is becoming more and more complex. Take new laws and legislation such as the revised EU Urban Waste Water Treatment Directive which has imposed a lot of new or stricter measures. And the Water Framework Directive is also expected to be revised. We have also established that it is now much more difficult to obtain permits than it used to be. And I am talking about both permits for our standard activities such as sewer projects and the three large industrial sludge processing plants which we got the green light for in 2024 after a long and intensive process.”

How is the company coping with that increasing complexity?

“By looking for simplification and standardisation in that more complex context. What I mean by simplification is primarily counteracting fragmentation in the sector. The mandate granted to us by the Flemish Region a few years ago to align municipal and supra-municipal investments helps achieve results quicker with the same resources. The infrastructures of the two policy levels have such a strong influence on each other that it is absurd not to look at them together. But synergy gains will become even greater if management is also carried out under one roof. Then it will also become possible to make savings on the execution of projects, for example. That is why we are looking to set up structural partnerships with all Flemish sewer operators. We already have them with water-link, De Watergroep and since 2023 with Pidpa too with whom we expanded collaboration last year. We are also already collaborating with Farys on a project basis and it would be great if we could develop this arrangement into a structural partnership too.”

“We are striving for more uniformity within the sector at the same time. For instance, in 2024 we brought drinking water companies and the Flemish Environment Agency together at an initial Blue Summit in order to consider digitalisation and automation together with us as well as the exchanging of data between the different water companies in order to enable the further integration of the Flemish water sector. We are all facing the same challenges, so we prefer to look beyond our own organisational boundaries.”

Last year, we also saw new activities such as sewer thermal energy take off. Where did that acceleration come from?

“Over the past few years, we have focused on broadening and deepening our activities for the purpose of responding to social challenges such as the energy transition and water shortages in long periods of drought. Examples include sewer thermal energy and the reuse of effluent, including opening up the availability of these via the new digital platform AquaMarkt. These new activities have brought us into contact with a type of client and stakeholder that is completely new to us. In the process, we also brought about some additional complexity ourselves, not least because even the legal framework is often still lacking for innovative partnerships of this type. Last year, we carried out truly pioneering work in order to get the procedures right and connect parties. It has paid off and interest in projects of this type is growing rapidly.”

What are you looking forward to in 2025?

“I can think of a lot of exciting topics coming our way this year but one of the big ones is surely the start-up of our first full-scale quaternary treatment at our Aartselaar WWTP. The initial plans date back at least five years to a time when we were already anticipating the future obligation to remove micropollutants such as certain drug residues from waste water. Our plants are not currently equipped for this and at the moment, there is no statutory requirement for us to do so either. However, these substances have an impact on the aquatic environment even in small quantities. And therefore Europe wants to see them removed in the future, hence the revised Urban Waste Water Treatment Directive. Moreover, Europe has placed the financial responsibility for this on the producers via whose products these substances end up in waste water. We have already entered into a dialogue with them about how we can tackle this together.”

“We are finding that our social playing field is getting wider and wider and we – literally and figuratively – are connecting to completely new sectors. For instance, our new sludge processing plants are being built on industrial sites where the residual heat produced will be both used by us and supplied to industrial plants such as the steel industry, for example. Incidentally, focus is increasingly being directed towards surface water quality, partly because of the ‘water ruling’ that has already led to a number of permits being refused. As a result, completely new stakeholders are constantly emerging for us. A challenging but interesting prospect.”

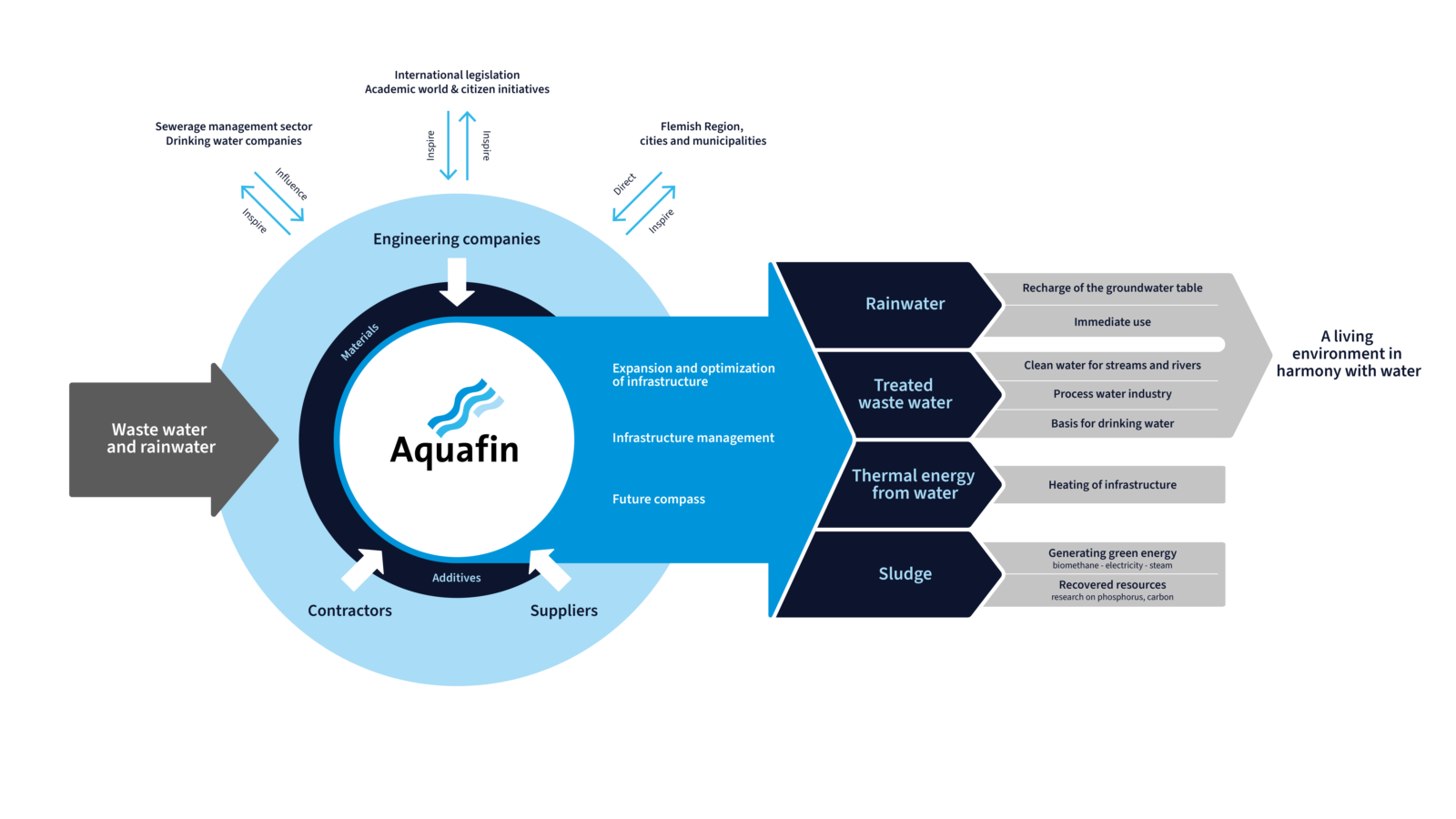

What we do

What we do

Projects for the Flemish Region

Aquafin is responsible for the development, financing and management of the regional infrastructure for the collection, transport and treatment of domestic wastewater in Flanders. Towns, cities and municipalities have to take care of the development and maintenance of the municipal sewer network to which residents connect their waste water.

Both Aquafin and the local authorities were given so-called reduction targets. The European framework states that all bodies of water must be in a ‘good state’ by 2027. Since 2024, Aquafin as taken on the role of matchmaker in order to improve the coordination of municipal and supra-municipal (regional) investments. This will enable the available resources to be deployed in the most efficient manner in order to achieve ecological objectives.

Prioritising projects according to their impact

Aquafin drew up a plan of approach for each body of water outlining the supra-municipal projects that needed to be carried out in order to achieve the reduction targets. However, a budget analysis shows that the current supra-municipal delivery budgets planned are not sufficient for this purpose. So in 2024, we devised a method of prioritisation that takes into account the reduction contribution of projects and specific deadlines as well as any other opportunities such as resolving flooding problems. Prioritisation was also applied to all ongoing projects which resulted in the updating of the project portfolio.

Further refinement of the methodology is on the agenda for 2025. Each project is currently linked to the body of water it impacts most while that impact may be wider. The correct distribution of that impact will help us prioritise projects even better. In addition, we are also working on a dashboard for tracking progress in respect of meeting reduction targets as well as on a simulator that will allow us to compare scenarios with each other. For extra domestic wastewater connections to the sewer system are only one way to achieve reduction targets. Two other routes are the reduction of overflow operation and the removal of even more nutrients from the treatment process.

The graphs below show the reduction contributions of our investment and optimisation projects for nitrogen (N) and phosphorus (P) up to and including 2024, categorised by prioritisation class of the watercourses.

Nitrogen (N) Reduction in the Watercourse

Phosphorus (P) Reduction in the Watercourse

Agreed project volume realised

In 2024, we managed once again to realise the whole planned delivery budget of 174 million euros for investment and optimisation projects. That is a major challenge in the current volatile context we are working in. We therefore monitor the status of projects continuously and proactively make adjustments in order to ensure that we can deliver the agreed budget on time. In the coming years, the Flemish Region foresees a gradual increase in delivery budgets. The target for 2025 is 180 million euros.

In 2024, we also put a total of 334 million euros worth of new projects out to tender. That is well above the target of 260 million euros.

Innovative site approach

The climate impact of building materials and the increasingly complex context in which infrastructure works are being carried out has prompted us to think about taking a different innovative approach. In an initial project to be launched in 2025, we will be testing concepts for optimising communication with the neighbourhood and safety on and around the site. A second project will serve as a testing ground for organising site activities in a more environmentally-conscious way and for the more sustainable use of materials.

We collected numerous concepts for the two projects via our internal platform for innovative ideas and we will investigate and develop those concepts further with our technical partners. As one of the major clients for infrastructure works in Flanders, we can therefore take on a pioneering role in order to make infrastructure (works) more environmentally-friendly.

The path to clean water

Our large collector sewers collect domestic wastewater from the municipal sewers and transport it to one of the 330 wastewater treatment plants that Aquafin had in service on 31 December 2024. There it undergoes a mechanical treatment process followed by a biological treatment process in order to comply with Flemish and European standards so that it can then be discharged into surface water. This is still carried out almost everywhere.

But it can also be upgraded for any application, even to drinking water quality. Drinking water company Aquaduin has been producing drinking water from the treated wastewater or effluent from our WWTP in Koksijde for more than 20 years. Interest in effluent as a basis for industrial applications such as cooling water or process water has increased over the past few years. Several major reuse projects that are currently under development are due to be launched in the coming years.

Good treatment results despite wettest year on record

The treated wastewater is assessed based on 3 to 5 parameters, depending on the capacity of the WWTP (see box). For most parameters, there are both concentration limits as well as removal percentages to be attained according to Flemish standards.

When it rains a lot, the wastewater is therefore highly diluted with rainwater and the infiltration of groundwater into the sewers also results in dilution. Therefore the concentration of substances to be removed in the incoming sewage water is sometimes lower than the concentration limit that applies to discharging into the watercourse. In that case, and in order to achieve the removal percentage, it is necessary to add extra chemicals. In the evaluation of the treatment results in respect of removal percentages, influent samples that are too highly diluted are not included, by agreement with the Flemish Environment Agency.

In 2024, 320 of the 329 WWTPs evaluated complied with all the standards. Of the other 9 WWTPs, 8 achieved all the concentration limits as well as 4 of the 5 removal percentages. Only 1 WWTP failed to achieve 1 of the 5 concentration limits due to sludge leaching but did meet all the removal percentages. As 2024 was the wettest year on record in Belgium according to the RMI, these are excellent treatment results.

WWTPs that meet the Standards

Challenging year for sludge processing

The micro-organisms that absorb the dissolved impurities in the biological treatment process grow continuously. We have various processing routes for the excess sludge produced as a result.

After thickening at the WWTP, half of the biomass goes to one of our 13 digestion plants. We convert the biogas into green electricity and heat by means of cogeneration (CHP) and currently into biomethane at one location. In 2025, we will be replacing cogeneration with biomethane production at 3 additional WWTPs.

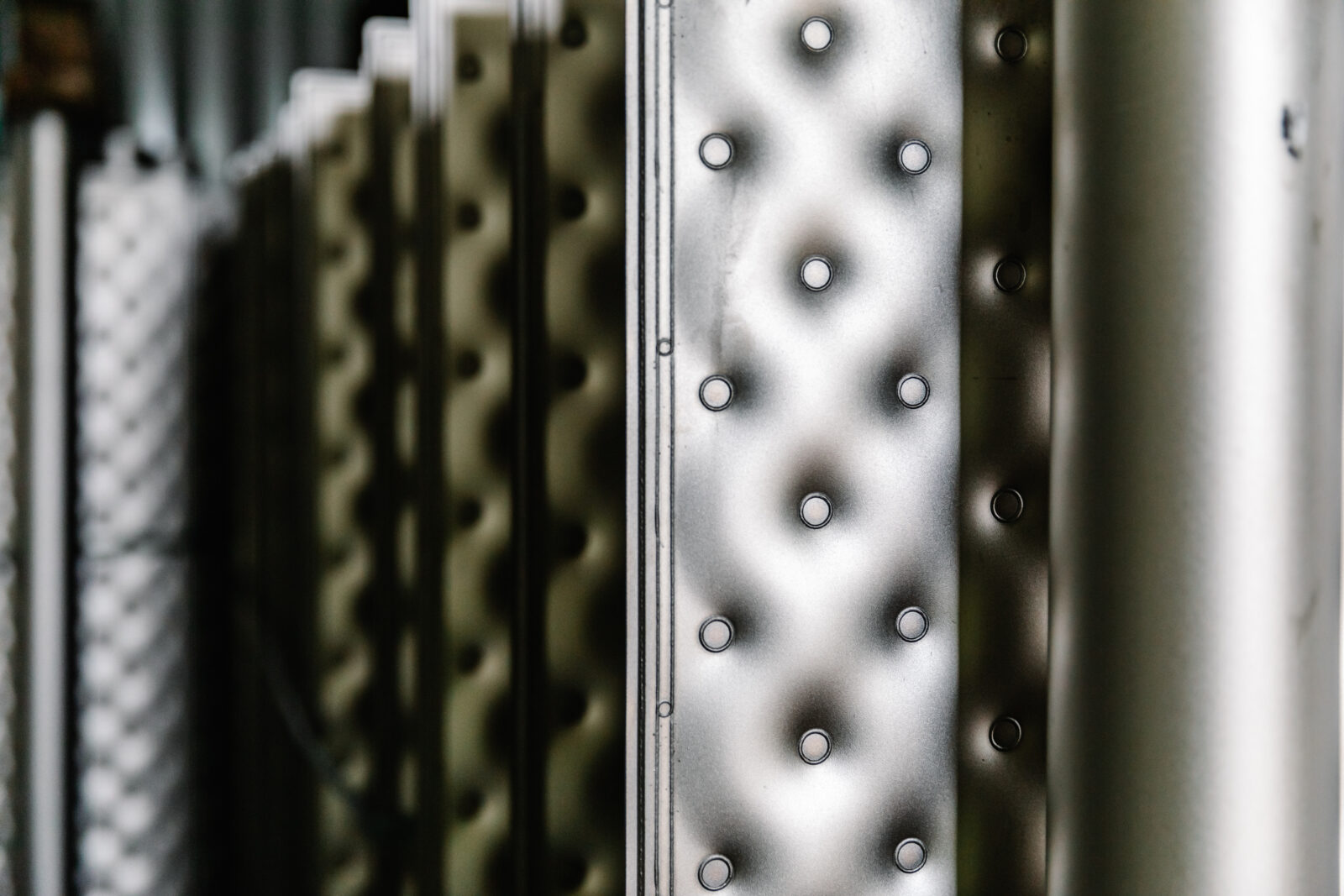

During the next stage, as much water as possible is extracted from the digested sludge and the undigested sludge so that the volume shrinks further. In the final processing phase, two thirds is incinerated and one third of the dewatered sludge goes to one of our three current sludge dryers. Here it ends up as pellets with a high calorific value which are used as a renewable energy source.

The larger the flow of sewer water we process at our WWTPs, the more sludge we produce. But the increased removal of phosphorus in the treatment process of 50 WWTPs also leads to more sludge. We ended 2024 with no less than 9% more dewatered sludge than the previous year, which already was extremely wet. This shows in the the much higher costs for chemicals for thickening and dewatering the sludge, for transportation and for sales. We even got close to our capacity limits for final processing in Flanders which meant we had to start looking for extra capacity abroad. With the start-up of two new sludge dryers that run on residual heat and a sludge mono-processor from 2027, the final processing of our sludge in Flanders over the coming decades is guaranteed.

Parameters for clean water

BOD

biological oxygen demand – the amount of oxygen required to break down the pollution biologically.

COD

chemical oxygen demand – the amount of oxygen required to break down the pollution via a chemical process.

Suspended solids

all undissolved substances in a volume of waste water.

Nitrogen & phosphorus

nutrients present in domestic waste water. Excessive quantities of these in the watercourse lead to strong algae growth which reduces the oxygen content.

Taking current prices into account, the reinvestment value of the infrastructure that Aquafin manages for the Flemish Region currently stands at around 10 billion euros. Huge investments that must continue to pay off. Due to the ageing of the infrastructure, there is logically an increasing need for maintenance, renovations and replacements in order to continue to guarantee proper functioning. But new legislation and improvements in efficiency can also prompt optimisations.

State of every asset is known

We determine which investments are most urgent based on the state and age of the various assets (asset health index) and draw up a programme for replacement. Having previously carried out this exercise for pumping stations and the sewer system, we did the same for WWTPs in 2024. So now we have a clear picture of the state of health of more than 30,000 individual assets. That picture is based partly on inspections such as camera images of sewers and partly on the theoretical expected lifespan. In the coming years, we will further enhance it with findings made during visual inspections. However, the picture that we currently have already shows that here too, the budgets planned for the next few years will not be sufficient and an investment backlog is building up that will only continue to grow. This is due to the big wave of investments from the ’90s onwards. Those assets are now increasingly in need of renovation or replacement. We have also seen significant increases in the pricesprincing of such projects in recent years. In 2024, we delivered asset management projects for the whole planned amount of 54.3 million euros.

Energy savings for infrastructure

The water treatment process requires a lot of energy for pumping and the biological process of breaking down the pollution in the waste water by means of aeration, for example. We constantly optimise our energy consumption through our continuous focus on the energy efficiency of process settings and the close monitoring of consumption. We can also use funds from the Energy Fund to improve the energy performances of the infrastructure every year. The fund is fed by the payback effects of previous investments in energy efficiency or production of green electricity. These investments bring an annual saving of 20 GWh of electricity and provide an additional 17 GWh of green electricity production. In 2024, we invested just under 6 million euros in projects with that objective, a significant proportion of which went into the construction of PV installations and energy-efficient controls for aeration at WWTPs.

Energy figures: see sustainability report.

Action plan for mitigating overflow operations

Untreated wastewater can escape into the watercourse via emergency outlets from the sewer system – so-called overflows – and cause ecological damage. An overflow starts to work when the sewer overflows. This may be due to an excessively high flow volume caused by heavy rain but it can also happen in dry weather if the flow of water is impeded by a blockage, for example.

At the beginning of 2025, Aquafin completed the installation of 1,600 overflow gauges. These provide information on the frequency, duration and flow in respect of overflow operation. On the one hand, they will enable us to detect a blockage in the system much quicker so that we can take action and thus limit the environmental impact. But overflow measurements reveal nothing about the exact impact on the watercourse. With the help of Cockle, a calculation tool that we have developed in-house, we can estimate the actual waste load emitted properly. In 2024, we carried out an initial, large-scale analysis on 4,000 overflows into watercourses which should comply with the Water Framework Directive the soonest. This has shown that 15% of those overflows require priority action and a small minority are truly problematic. Lack of storage capacity and overflow sills that are too low are often the cause. Cockle helps us compare different remedial measures which could involve expanding storage capacity, disconnecting rainwater and canals that are connected to the sewerage system, smart sewer water control or the after-treatment of overflow water. We are currently testing various after-treatment technologies in trial projects.

Sludge processing of the future under construction

From 2027, the final processing of our sewage sludge will be completely fossil-free. Last year we started the construction of two new sludge dryers that will run on residual heat from waste processing. They will replace the current sludge dryers in Deurne, Leuven and Houthalen which are coming to the end of their service life and still run on natural gas to a large extent. The new dryers are being installed in Beringen, with residual heat from Biostoom Beringen, and in Roeselare where we will connect to Mirom’s heat network.

The dried sludge will be used in our new sludge mono-processor to help produce high-pressure steam. This plant has also been under construction since the end of 2024, at the ArcelorMittal site in Ghent. Here, two thirds of all the sludge will be incinerated and energy and steam will be recovered, with the latter being supplied to the steel producer’s steam network for use in the production of ‘green steel’. With the construction of the sludge mono-processor, we can be sure of the guaranteed sale of two thirds of all the sludge in Flanders, at least until 2046 when the DBFMO contract (design, build, finance, maintenance and operations) with our partner FOSTER comes to an end. That is an important guarantee given the limited final processing capacity in Flanders and even beyond.

In the meantime, we have also been investigating how we can recover phosphorus from ash in the flu gasses from incineration in a subsequent process. Phosphorus ends up in waste water via human urine which accounts for its presence in sludge. It is used in artificial fertiliser in the form of phosphate.

What we do

Increasing impact with our clients

Latest rainwater plan completed

By the end of 2024, towns, cities and municipalities had to have a rainwater plan in place in order to still be eligible for water-related subsidies. Flanders imposed this obligation in 2020 although Aquafin started drawing up its initial plans back in 2015. It was at that time that we first saw signs of a changing weather pattern and a number of municipalities then also followed our vision. By the end of 2024, we had completed more than 100 rainwater plans in total. These plans will have to be updated at least every six years based on new insights and indicators. For Aquafin, since the structural partnership with Pidpa was set up, they also include the plans made by the drinking water company for 50 municipalities.

Climate-adaptive design in practice

Due to long periods of drought and extreme rainfall combined with too many paved surfaces, the approach to rainwater needs to be adjusted. To this end, Aquafin has firmly opted for ‘blue green’ solutions: more space for water, preferably combined with softening and ample greenery.

That is because this formula offers a lot of opportunities for linking , among others things, to biodiversity, recreation and both physical and mental health. Not only do we share this vision in our rainwater and drought plans for municipalities, we also publicise it as much as possible via other channels such as the Blauwgroenvlaanderen.be website (see box) and initiatives such as De Zevende Gevel and Green Deals Tuinstraten and Klimaatbestendige Omgeving.

Via specific services such as our water and environmental advice, the implementation and maintenance of small-scale blue green measures and the realisation of a garden street, we are turning that vision into practice for municipalities but also for companies and organisations. In 2024, we provided 36 water and environmental recommendations.

The first Sewer thermal energy projects in Sint-Niklaas and Mechelen

Sewer thermal energy is the technology for recovering energy from waste water either in underground sewers or in the pipes via which the treated waste water is discharged into the watercourse. A heat exchanger in the pipe uses a conductive liquid to transfer the residual heat from the water from showers, washing machines, etc. to a heat pump that is used to heat or cool buildings. It is a constant, reliable source of energy recognised by the Flemish Energy and Climate Agency (VEKA) as a renewable energy source. Interesting for local authorities as it allows them to use sewer thermal energy to shape their heat plan for the Local Energy and Climate Pact (LECP) with the Flemish government.

After initial implementation at our own offices, we carried out our first sewer thermal energy projects in public locations in 2024. In Sint-Niklaas, we installed sewer thermal energy for the new swimming pool under construction and for the municipal pavilion at the same sports venue. In Mechelen, a completely new urban district with residential, office and commercial units will be heated and cooled by sewer thermal energy supplemented by geothermal energy. It is the first time that the two techniques have been used together on this scale in Europe.

Also in 2024, we brought all the Flemish sewer operators together in order to visualise the sewer thermal energy potential of the sewers under their management, using the digital platform AquaMarkt. If the estimated 400 eligible projects are also carried out, that will mean an annual reduction in CO2 emissions of 40,000 tons per annum for Flanders.

First project for reusing effluent this year operational

The treated waste water from our WWTPs (effluent) is of constant quality and always available. That makes it an excellent alternative water source for any application as long as appropriate further treatment is carried out.

.To encourage industrial reuse of effluent as a circular solution in water stress-susceptible Flanders, we unlocked its potential via the digital platform AquaMarkt. Parties interested in making use of it can submit a request via the website and we then issue a call (final call). We then go through an objective and transparent allocation procedure before allocating the effluent to a party. Thirteen concrete projects have been allocated to date, the majority of which are in the permit phase.

The Deeper Blue project at our Aalst WWTP is already well advanced and is expected to be completed in summer 2025. From then on, drinking water companies Farys and De Watergroep will further treat the effluent from the WWTP at the site themselves to produce drinking water. The system will serve as a winter-summer battery for drinking water and thus help guarantee that there is sufficient drinking water on the coast in summer.

Residual water for agriculture and horticulture

We were tasked by the Flemish Region with making ‘residual water’ such as rainwater in buffer basins available for agriculture and horticulture. With smart controls or minor intervention at the basin, we can guarantee a good balance between the functions of a buffer basin: storing rainwater to prevent flooding and to enable beneficial reuse.

We mapped the potential of more than 30 basins based on water quality, water availability and interest. If there is sufficient potential, we draw up a project plan as the first step towards design, contracting and implementation. At the end of 2024, project plans had been drawn up for three basins, ready for an agreement with the customers. An initial concrete project went into production in Sint-Niklaas at the start of 2025, and we are expecting to be able to start using it by the end of this year.

What we do

Connector in the water and utility sector

Structural partner of sewer operators

The efficiency gains from the better alignment of municipal and supra-municipal investments become even greater if they are also managed together. That is, for example, when coordinated project management becomes possible. Those efficiency gains are quite evident in Aquafin’s structural partnerships with drinking water companies water-link, De Watergroep (Riopact) and – since 2024 – with Pidpa as well.

Aquafin’s ambition for the future is to set up a structural partnership with all the municipal sewer operators. Last year, we formed a consortium with Farys for the second time for managing a city’s sewers. Following in the footsteps of Aalst, Dendermonde has now also entrusted the management of its sewers to the Farys-Aquafin partnership.

Platforms for a clear view of the state of the sewers

By 2027, the Flemish Government wants to have a clear picture of the state of the Flemish sewers. Aquafin worked with the sector to devise standards and minimum requirements for sewer inspections. On the website statustool.aquafin.be you can find with an overview for each municipality showing the state of the system and the progress of the inspection programme.

Municipalities who partner with us for their asset management can also use the digital platform ROSI which gives them a transparent view of the schedule for and performance of inspections on their sewer system. Here, they can also find proposed measures, including timing and budget. We are currently offering this support to half of all Flemish municipalities, towns and cities. We are planning to develop ROSI further in 2025 by adding functionalities that go a lot further than sewer inspections, such as data from our overflow measurement matrix, for example.

The fluid exchange of water data

If we are to improve water management in Flanders, we have to work with other actors in the water sector, we are working on a Flemish Water Data Space, in which all the partners’ data can be exchanged smoothly and securely. In data spaces, each partner retains control over their own data in a decentralized en secure manner

One platform for sewer management

Pidpa and Aquafin are jointly responsible for managing the sewers of 50 municipalities. Within our structural partnership, we are currently working on a digital platform for combining our data. Not only will this make collaboration simpler, it will also enable challenges such as cyber security and energy consumption to be tackled more efficiently.

“Everybody is facing the same challenges, so we prefer to look beyond our own organisational boundaries.”

Jan Goossens, CEO

What we do

Research and innovation

At Aquafin, research can be part of an innovation process but it can also be purely focused on building knowledge for the purpose. In any case, our research and our innovations are aimed at creating added value for people and the environment. Thanks to our broad heritage and our practical knowledge, we are a prized partner in the world of research for the long-term testing of new technology on a large scale and subsequent implementation.

“Our research focuses on broadening and deepening our activities for the purpose of responding to social challenges” – Birgit De Bock, manager R&D

Research in relation to water quality

The new EU Urban Waste Water Treatment Directive (ERSA) imposes the obligation for member states to remove a list of additional micropollutants in the future that are not stopped by current treatment technology, for example. In 2024, Aquafin finalised the construction of a first full-scale quaternary treatment plant for removing micropollutants using a combination of two technologies: ozonisation and activated carbon filtration. The plant will be in operation in spring 2025. We will be able to share our expertise with other research partners in Flanders and the Netherlands through our participation in the European Interreg project Clean Watercourses through O3G.

WBesides centralised treatment technologies, we are also investigating the possibilities of decentralised technologies for treating not only waste water but also rainwater and overflow water.

Climate mitigation and adaptation

We map greenhouse gas emissions in both the treatment process and the sewer system by means of research and measurement campaigns. Initial calculations already provide a good indication of the right strategic choices to make for mitigation. In the future, we want to use the calculations to apply them even more in the purchasing process and thus make our infrastructure more sustainable.

Our climate adaptation research focuses on water quantity with the modelling of sewer systems, including the use of precipitation data and forecasts, and the impact of overflow operation and possible source measures.

Recovery of raw materials

There are other raw materials that can be recovered from waste water treatment besides treated waste water. the new ERSA will impose the recovery of nitrogen and phosphorus in the future. Aquafin has been investigating the possibilities for removing these and other substances from the process for a long timen and how to make them cost-effective. For instance, we are currently exploring the possibility of selling recovered phosphorus for use in the production of artificial fertilisers.

We can also remove activated carbon which we use ourselves from the sewage sludge. In an ongoing innovation project, we are aiming to build a pyrolysis plant to process the sludge under extreme heat with thermal energy to produce biochar, a type of charcoal that can take on the function of activated carbon. Also, the advantage with the pyrolysis process is that CO2 is captured in the biochar rather than released. We are hoping to have more clarity regarding the financing of this by the end of 2025. WIn the meantime, we have been collaborating with external partners and testing the valorisation of biochar from sewage sludge as a sustainable element for concrete production and as an adsorption material in the treatment process.

We are investigating another form of carbon capture in the European project Fuelphoria. A pilot plant for turning the CO2 from the biomethane process into acetic acid via fermentation Acetic acid can serve as a source of carbon in the water treatment process or after further fermentation to form fatty acids, it can be used as the basis for biodiesel production.

Innovations make our infrastructure even more efficient

Apart from a limited budget for basic research, Flanders has not earmarked any funds for innovation that Aquafin can access. In 2024, we therefore invested 1.4 million euros of the profit on our municipal activities in financing innovation projects. Those innovations may lead to new business but often also increase the efficiency of our infrastructure for Flanders. Innovation Manager Maarten Raemdonck gives AquaMarkt as an example: “Treated waste water, rainwater, heat from sewers: all goods that lend themselves perfectly to reuse and that we are currently still allowing to drain out of Flanders far too much. We wanted to give that circularity a boost by bringing all of these together on a single digital platform and mainly also by devising a clear procedure that gives everyone equal access to these common goods. And it works, as with 500 unique visitors per month on average, in 2024 AquaMarkt brought no less than 17 new leads for reusing common goods since its launch in March.

Aquafin also wants to encourage innovation within the sector by collaborating on the development of new technologies for sewer inspections and investing in them via Aqcelerator, for example. For the classic method with a moving camera, the sewer has to be emptied first, which makes inspection expensive and time-consuming. The high demand for inspections due to the Flemish obligation has put pressure on market capacity. Screenings using drones, hovercrafts or robust carts for which the sewer does not need to be emptied, can provide an initial reliable picture of the state of the sewer. This can limit the number of thorough inspections for which the sewer does need to be emptied. To advance the development of new technologies as well as new sustainable materials, we will open up our infrastructure as a testing ground.

“In any case, innovation is not something that is kept under wraps at Aquafin,” says Maarten. “We actively encourage our employees to have an open mind and offer training and support to enable the further development of creative ideas. It doesn’t always have to be big new things; improving efficiency in your day-to-day work has just as much impact.”

Financial report

“We are ready to invest in innovations that increase our impact even further.”

The wettest year on record in Belgium is reflected in substantially higher operating costs at Aquafin. Finance & Procurement Director Glenn Van Olmen observes that innovation is necessary to tackle not only the material risks but also the financial risks of climate change.

Aquafin’s operating budget is under increasing pressure. Why is that?

“The shortfall in the operating budget in 2024 is a direct result of the exceptional weather conditions. A high level of precipitation leads to larger flows of sewer water that need to be handled. This in turn leads to larger volumes of sludge to process and more chemicals that are required to achieve the double standards in Flanders. Fortunately, not every year is so wet and in the past, the budgetary impact of a wet year was generally compensated for by a subsequent dry year. Only we have seen that in recent years, that compensation has no longer been in proportion. The last really dry year is once more already behind us. We can assume that extremes like the ones we saw again last year will become the new normal.

Add to that the fact that our assets are ageing and therefore are only going to need more maintenance. In addition, increasingly strict standards and new legislation are also forcing us to use more additives. All factors that make water treatment more expensive and which we cannot easily control despite close monitoring.”

What role can innovation play in keeping everything feasible and affordable?

“There is certainly a key role for innovation but unfortunately, Aquafin does not currently have a specific innovation budget. We do have a budget for fundamental research but innovation is necessary for the further development of research results. And that will certainly be necessary to comply with European directives.

We currently use the profit from our commercial activities outside our supra-municipal remit to finance innovation. And last year that amounted to a fantastic 2.8 million euros, including both income from our activities for municipalities and from newly developed services. We have also noticed that innovation can really advance our supra-municipal activities. For instance, our business case around the production of biomethane from sludge digestion helped in the permit process of certain WWTPs, for example. That way, our innovations also pay off for the Flemish Region.

Of course, we also see a lot of innovations that support our vision emerging outside Aquafin. We want to literally speed them up by giving them a nudge through our new subsidiary Aqcelerator.”

How can Aqcelerator serve as a lever to boost Aquafin’s impact?

“We set up Aqcelerator with two objectives in mind. On the one hand, parties that have been allocated common goods such as effluent can then approach Aqcelerator to see how financial participation in the project could be of interest. On the other hand, we also want to stimulate innovations in the market that will help us realise our ambition. And that could be participations in start-ups, for example. I also want to stress here that Aqcelerator is completely separate from our contract set by decree where our own Board of Directors monitors market conformity.”

What opportunities do Aquafin’s challenges present for investors over the next few years?

“Given the expectations from Europe, the number of projects that we will realise over the coming decades will only continue to grow. The Flemish Region foresees a gradual increase in investment budgets for this purpose. That will create opportunities for our financing partners as we prefinance all projects for the region. We also want to engage our investors more again, because financing is and will remain a core activity. Differentiation of our sources of financing is therefore much needed.”

Won’t the visibly shifting focus on defence due to geopolitical developments be at the expense of investments in sustainable companies?

“I don’t expect that development to pose immediate risks for Aquafin in any way with regard to getting our projects financed. We have noticed that investors are increasingly looking to make their portfolios greener. Europe has expressed clear ambitions with the Green Deal, and the intrinsically green value of our projects fits in perfectly with this. Incidentally, increasing digitalisation and cyber threats will require us to invest in the digital security of our infrastructure even more. Waste water infrastructure is regarded as highly critical in NIS 2. Therefore, we do everything we can to keep risks under control and ensure that the impact of our work is always guaranteed.

Our allocation agreement also gives financiers the necessary guarantees and our excellent Moody’s rating of Aa3 boosts confidence even more.”

Key figures financial report

Balance sheet and income statement

| in mio euros | 2024 | 2023 |

|---|---|---|

| Operating income | 724,230 | 722,374 |

| Operating charges | 646,559 | 651,159 |

| Turnover | 673,066 | 662,058 |

| Profit for the financial year available for appropriation | 4,435 | 4,877 |

| Total income statement | 4,125,022 | 3,965,178 |

| Capital and reserves | 328,465 | 328,243 |

| Short-term financing | 150,102 | 53,101 |

| Long-term financing | 2,410,250 | 2,342,212 |

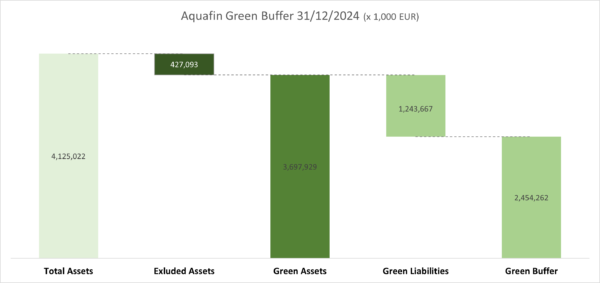

Green Finance Framework report